Axial Cutting: How It Delivers Power and Precision

What do rock excavation, pipeline trenching, and wastewater management have in common?

They all rely on the power of axial cutting to get the job done right. Unlike radial cutting, which spreads force outward, axial cutting directs it along a single axis, making it ideal for rock grinding, trenching, and industrial applications.

At the core of this cutting-edge technology is the axial drum cutter, a high-torque machine built for tough materials with minimal risk to surrounding structures. Its controlled cutting process, like a well-planned camera angle in film, keeps every shot smooth and efficient.

This article breaks down how axial cutting works, where it excels, and why it’s the go-to system for demanding jobs.

Key Takeaways

- Axial cutting delivers precision and power, making it the best choice for rock grinding, trenching, and excavation in tough environments.

- Rockwheel axial drum cutters focus all cutting force into a single drum, providing clean, controlled cuts with minimal vibration.

- RockZone Americas leads the way in cutting technology, offering durable, high-performance solutions for demanding excavation projects.

Axial vs. Radial Cutting: Why Precision Matters

Think of axial cutting like drilling straight down into a surface. The tool moves parallel to the spindle, making it perfect for tasks that need depth and accuracy, like boring holes or reaming to get the exact diameter needed.

Radial cutting works perpendicular to the spindle. It’s great for shaping surfaces, smoothing edges, and making precise lateral cuts. Instead of cutting straight in, it moves along the surface, handling jobs like milling and facing with ease.

Key advantages of axial cutting over radial cutting

- Superior depth control: Ideal for applications requiring consistent penetration, such as boring deep holes or reaming for exact diameter specifications.

- Efficient material removal in vertical operations: Axial tools work efficiently when cutting directly into a material, reducing excessive lateral force.

- Improved structural integrity: Creates cleaner cuts without unnecessary stress on surrounding material, maintaining continuity in the workpiece.

- Precise alignment for complex machining tasks: Works seamlessly in CNC systems designed for intricate drilling and finishing operations.

Axial Cutting in Action: Where It Excels

Axial cutting is designed for precision in tough environments. From vertical rock grinding to narrow trenching, it’s a go-to method for jobs that require accuracy and control.

Rock and concrete grinding: Axial drum cutters are built for vertical cutting applications, making them ideal for grinding concrete piles, shaping columns, and handling demolition work.

Their high-torque design ensures clean, controlled cuts while keeping vibrations low to protect surrounding structures.

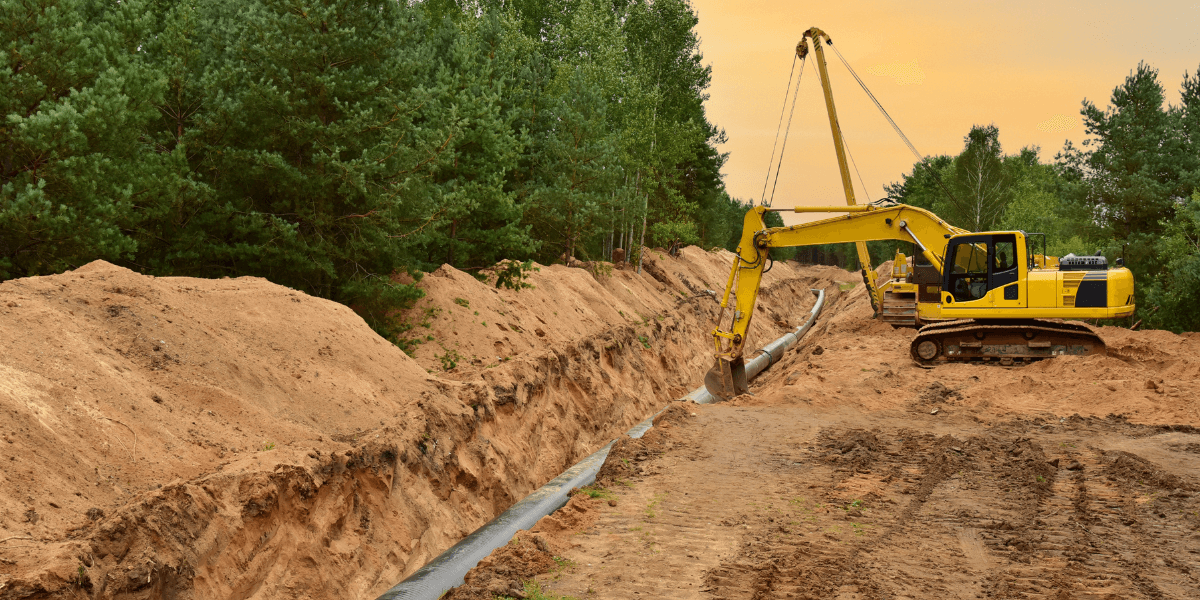

Trenching & pipeline construction: When traditional twin drum cutters are too wide, axial cutting provides a better solution for narrow trenching and vertical holes.

Its precise cutting action keeps the excavation clean, minimizing unnecessary material removal and reducing extra cleanup.

Mining and tunneling: Axial drum cutters play a key role in underground excavation, offering controlled cutting in confined spaces. While both axial and radial cutters are used in mining and tunneling, axial cutting is especially useful for deep, vertical cuts where accuracy is critical.

Specialty applications: Axial cutting extends beyond standard excavation. It’s used in underwater excavation, soil mixing (with specialized mixing blades), and other precision-driven tasks. Its adaptability makes it an essential tool in engineering, construction, and infrastructure projects.

The Engineering Behind Axial Drum Cutters

Axial drum cutters are built for precision and power in cutting applications where traditional twin drum cutters are too wide or not properly aligned. Their single-drum design focuses all cutting force in one direction, making them ideal for vertical holes, narrow trenching, and grinding concrete piles or rock formations.

The power of hydraulic motors

A high-torque hydraulic motor drives each cutter, delivering strong, controlled cuts with minimal vibration. Unlike twin drum cutters, axial models concentrate all power into a single drum for efficient material removal.

The Rockwheel AX20 (95 hp) and AX30 (150 hp) models are built for 18-35 ton excavators, providing reliable cutting force for demanding jobs.

Precision in design

Axial drum cutters are made for tight spaces and tough materials. Their in-line cutting orientation allows for clean, vertical cuts without unnecessary material displacement.

They are well-suited for narrow trenching, soil mixing, and trimming arched profiles, making them a go-to solution for detailed excavation work.

Durability & longevity

These cutters are built to perform in extreme conditions. Their rugged construction allows them to grind through rock, work in underground excavation, and operate in underwater environments.

With low noise and vibration, they are a strong choice for projects in sensitive areas where minimizing disruption is a priority.

Which Axial Drum Cutter Is Right for Your Job?

Not all cutting jobs are the same, and the right axial drum cutter depends on several key factors.

The size of your excavator, the type of material you’re working with, and the environment all play a role in choosing the best model. Here’s what to keep in mind.

- Excavator compatibility: Axial drum cutters need to match the power and hydraulic flow of your machine. The Rockwheel AX20 is designed for 18-25 ton excavators, while the AX30 is built for 25-35 ton models.

- Cutting depth and width: Different jobs require different cutting capabilities. If your project involves narrow trenching or grinding deep into rock or concrete, choosing a model with the right diameter and cutting force is essential.

- Environmental factors: Some worksites require maintaining low noise and vibration levels. If you're working in a sensitive area, an axial cutter’s precision and controlled movement help reduce the risk of damaging nearby structures.

AX20 or AX30? Choosing the best fit

The right axial drum cutter depends on your excavator size, cutting demands, and site conditions.

The AX20 is built for 18-25 ton excavators, delivering 95 hp of cutting power with a 26-inch drum. It’s a strong choice for mid-size projects like rock grinding and narrow trenching. For tougher jobs, the AX30 steps up with 150 hp, a 27-inch drum, and more torque. Designed for 25-35 ton excavators, it’s built for deep cuts and high-performance excavation.

Both models provide precision and controlled cutting, but the best choice comes down to the specific requirements and scale of your project.

Why RockZone Americas Leads in Axial Cutting Solutions

At RockZone Americas, we have spent over 50 years providing high-performance cutting solutions for construction, mining, and environmental projects. Our Rockwheel axial drum cutters are built for precision and power, making them the right choice for vertical cutting, narrow trenching, and grinding through tough materials.

Unlike twin drum cutters, our axial models focus all cutting force into a single drum, delivering high-torque performance with minimal vibration. This allows for cleaner cuts and less disruption in demolition, soil mixing, and underwater excavation. Our cutters are designed for extreme conditions, keeping noise and vibration low for sensitive environments where accuracy matters.

Get a quote today!

Looking for the right cutting attachment for your next project? We offer rental and purchase options to fit different needs. Contact us today for expert recommendations and find the best Rockwheel cutter for the job.

Conclusion

Axial cutting delivers precision and power, making it the best choice for rock grinding, trenching, and excavation in demanding environments.

With a single-drum design, Rockwheel axial drum cutters focus cutting force in one direction for clean, controlled results. This accuracy helps maintain continuity in excavation, reduces unnecessary material removal, and keeps projects moving efficiently.

RockZone Americas provides cutting solutions built for performance, durability, and reliability. Rockwheel cutters handle tough jobs with power and precision, giving operators the tools needed for efficient excavation.

When the job calls for accuracy and strength, axial cutting is the answer, with RockZone leading the way.

Frequently Asked Questions

What is a drum cutter used for?

A drum cutter is used for precision cutting, grinding, and excavation in materials like rock, concrete, and asphalt. It attaches to excavators and uses a rotating drum with cutting teeth to break down surfaces with minimal vibration.

Ideal for trenching, tunneling, demolition, and profiling, it allows for controlled material removal in tight or sensitive areas.

What is a rockwheel?

A rockwheel is a high-torque drum cutter designed for rock and concrete grinding, trenching, and excavation.

Unlike traditional cutting tools, a rockwheel focuses all its power into a single rotating drum, delivering precise and efficient cutting with reduced noise and vibration. It’s commonly used in construction, mining, and demolition projects.

What is a rock wheel trencher?

A rock wheel trencher is a powerful trenching machine built to cut through hard surfaces like rock, asphalt, and concrete. It features a large, toothed wheel that grinds and removes material as it moves forward.

These trenchers are commonly used for laying pipelines, cables, and drainage systems in tough ground conditions.

What is a rock rake?

A rock rake is an attachment for tractors and skid steers that clears rocks, debris, and roots from soil surfaces. It features curved tines that sift through the ground, collecting unwanted materials while leaving finer soil behind.

Farmers, landscapers, and construction crews use rock rakes to prepare land for planting, grading, or building.

What is a wheel digger?

A wheel digger, also called a bucket wheel excavator, is a massive machine used for large-scale earthmoving and mining. It features a rotating wheel fitted with buckets that scoop and transport material continuously.

These machines are commonly seen in open-pit mining, coal extraction, and large excavation projects.