Disturbance Free Rock Cutting Adjacent to Existing Foundation...Rockwheel Drum Cutters get the Job Done

With the economy on steroids in 2018, there is tremendous construction activity all over the United States. Washington, DC is no exception and we're seeing constant renewal where outdated buildings are giving way to new construction. This means demolition and foundation work in close proximity to existing structures. Care must be taken and disturbance minimized when working within inches (literally) of existing buildings which are occupied, functioning workplaces or residences.

Rockwheel excavator mounted rock cutting attachments (sometimes called drum cutters or cutterheads) are an ideal tool when both accuracy and productivity must be achieved simultaneously. In this case, a limestone bedrock foundation needed to be deepened immediately adjacent to an adjoining building footer. To avoid the risk of damage to the neighboring structure hydraulic hammers were not an option because of shock waves and vibrations that would be reverberate through the rock mass and concrete. This can result in cracks and unseen microfractures that weaken the foundation.

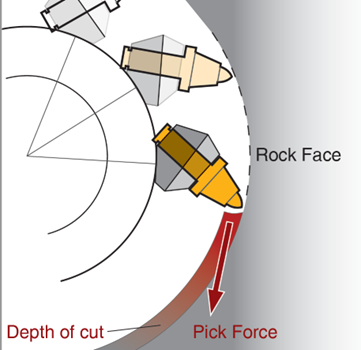

Attack angle of picks shears rock , allows smoother cutting and makes reusable cuttings

Rock grinding attachments attack the rock in a very different manner than hydraulic hammers. Unlike hammers (i.e. breakers), which go after the unconfined compressive strength (UCS) of the rock, the shearing action of the rotating conical carbide picks (teeth) exploits the tensile strength of the rock which is 10%-15% of the UCS. By "raking" the rock at 45-50o attack angle an added benefit is creation of smaller rock fragments and these cuttings can often be used onsite as backfill without crushing. This mechanical rock cutting or grinding results in significantly lower seismic disturbance which means safer rock excavation when close to buildings or other sensitive infrastructure such as gas lines.

Moreover, the degree of precision of rock or concrete cutting is exceptional. Rapid and Precise are two words frequently used to describe the cutting action of the Rockwheel drum cutters. Compared to other rock grinding attachments on the market the Rockwheel rock and concrete grinders have a optimal layout of teeth on the drums which results in a smooth cutting action. This means less frequent stalling of the cutterhead, more continuous rock cutting and ultimately more yd3/hr (m3/hr). For exceptionally hard material when pick penetration is hampered a demolition drum can be used which features a helical depth limiter which prevents the tool from try to take too big of a "bite". This less aggressive drum decreases vibrations and stalling of the cutterhead which means the Rockwheel is cutting rock a greater percentage of the time.

So...the next time you're faced with rock on concrete removal in a sensitive site where collateral damage is unacceptable give the experts at Rockwheel Americas a call. We'll gladly work with your local excavator dealer to ensure optimal hydraulic set up for peak performance of the rock cutting attachment. We have a national rental fleet and gladly work either customer direct or through your local equipment dealer. We maintain an extensive inventory so units can be delivery typically in less than 1-week. Rent, Purchase, or RPO (rental purchase option)...it's your call.