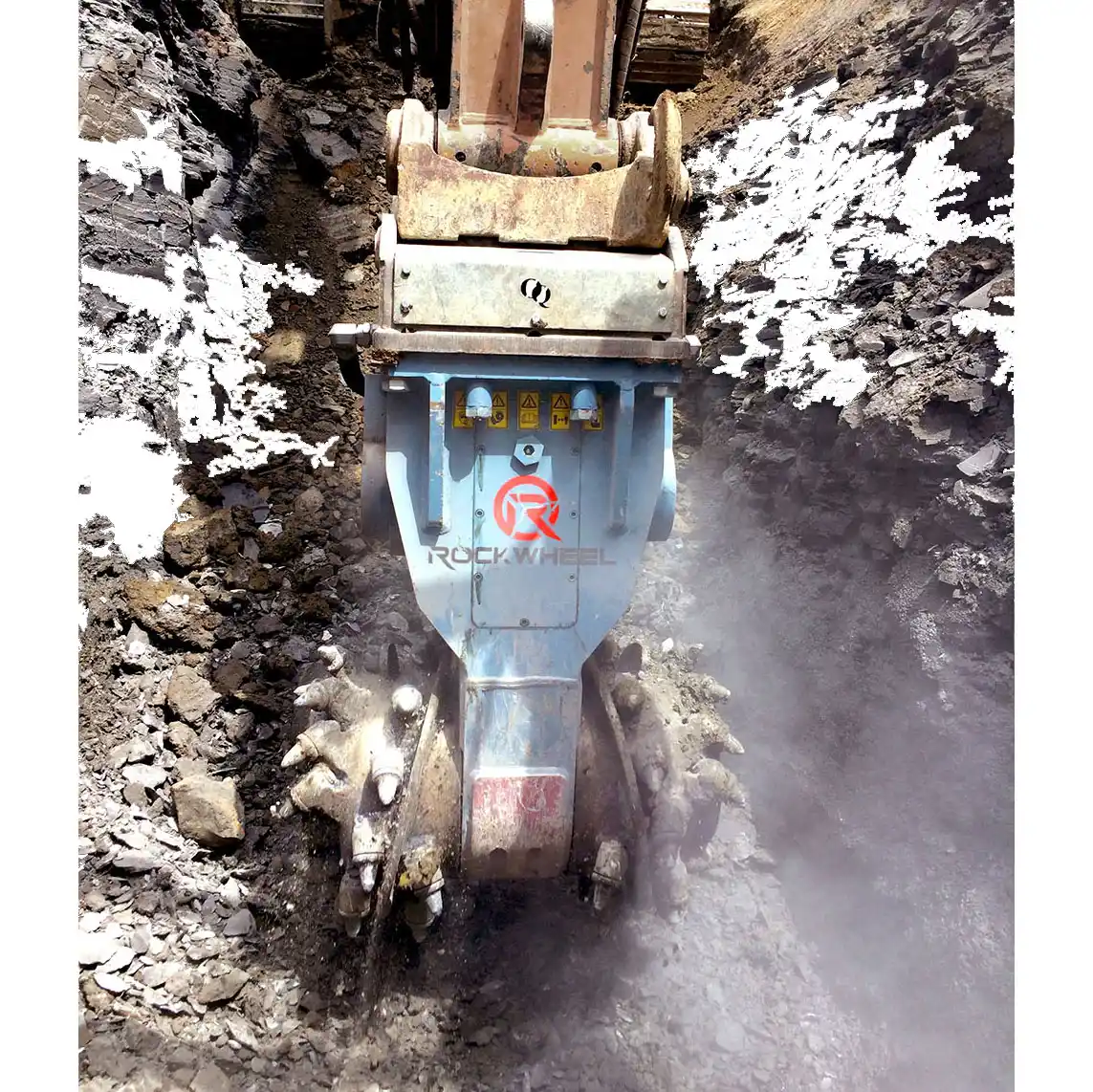

Rockwheel G50

190hp Grinder // 40 - 60 ton Excavators

The 190hp G50 cutter attachment with 41" cutting width gives your big excavators massively powerful rock and concrete removing capability. Compared to the G40, the G50 has wider and larger diameter drums that offer more cutting power and torque.

Specs

- 41" cutting width

| Rockwheel Model | G50 | |

| Excavator Class | tons | 40-60 |

| Required Flow Rate | GPM (l/min) | 85-110 (320-415) |

| Operating Pressure (Max) | psi (bar) | 5800 (400) |

| Gear Ratio | 1.2:1 | |

| Drum Speed | RPM | 45 - 75 |

| Max Torque | ft/lbs (kNm) | 31,695 (43) |

| Max Cutting Force | lbs (kN) | 26,613 (118.5) |

| Drum Width | in (mm) | 41 (1050) |

| Drum Diameter | in (mm) | 29 (726) |

| Picks/Bits | # | 56 |

| Weight (w/o bracket) | lbs (kg) | 5419 (2458) |

Engineered for heavy-duty applications and designed to tackle the most challenging conditions, the Rockwheel G50 drum cutter attachment is ideal for cutting hard materials like rock and reinforced concrete.

Whether you're grinding rock in tough terrain or cutting precise trenches near sensitive environments, this high-torque rotary twin drum cutter delivers powerful performance while minimizing vibration and protecting surrounding structures. This makes it ideal for excavation and demolition work on complex job sites where accuracy and durability matter.

Drum Cutter Attachment for Precision Cutting and Low Noise

The Rockwheel G50 drum cutter attachment features a hydraulically powered, gear-driven motor that delivers efficient cutting performance across rock, concrete, and other hard materials.

Durable internal spur gears ensure reliable torque and cutting force, even under pressure.

Ideal for noise-sensitive areas, this rotary drum cutter operates with low vibration, making it a smarter alternative to hydraulic hammers. Its quiet operation helps reduce noise and vibration exposure for crews working in populated or confined areas. Its 41-inch head width and engineered head diameter support high-precision trenching, rock excavation, demolition, tunneling, and mining.

Built with robust drums and optimized oil flow, the G50 offers accurate work, long-lasting performance, and the versatility to handle the most challenging conditions.

Reliable Drum Cutters for Demanding Jobs

Built for construction, mining, and tunneling, this drum cutter attachment delivers precise cutting with low vibration across concrete, asphalt, and rock. It handles tough materials with controlled force, making it ideal for heavy-duty applications.

An efficient hydraulic motor and optimized oil flow help reduce wear, lower the power required, and cut downtime, delivering measurable cost savings. Compared to traditional methods, this results in lower cutting costs and reduced disposal costs from minimized over-excavation. With durable drums and high torque, it performs reliably across varying depths and conditions.

More Than a Drum Cutter—A True Rock Grinder

The Rockwheel G50 isn't just an attachment—it's a high-torque rock grinder built for heavy-duty excavation through rock and reinforced concrete.

Its transverse drum and efficient hydraulic motor deliver smooth cutting with low noise and low vibration, which is ideal for sensitive sites. It’s an ideal solution for demolition projects where protecting surrounding structures is critical.

From trenching to deep material removal, the G50 offers the precision and power needed for demanding jobs.

Why Rockwheel Drum Cutters Stand Out

With over 25 years of continuous development, RockZone’s drum cutters are built for precision, durability, and reliable performance in excavation, trenching, and demolition.

These rotary drum cutters handle rock, asphalt, and reinforced concrete with low noise and minimal vibration, making them suitable for construction near walls or in sensitive areas. An efficient hydraulic motor and consistent cutting force reduce wear, lower the power required, and boost overall equipment efficiency.

Engineered for tough materials and accurate work, Rockwheel drum cutters are the ideal attachment for mining, tunneling, and heavy-duty construction.

Discover the Rockwheel Cutter Lineup

Rockwheel’s range of drum cutters is built for precise cutting, high torque, and compatibility with a wide range of excavator sizes. From compact trenching to large-scale rock excavation, these attachments handle tough materials with reduced vibration and maximum efficiency. Whether working with soft soil or hard rock, each cutter is engineered for high performance and low vibration levels.

Compact cutters for tight access

For smaller carriers, the Rockwheel C2 (12.7hp) is ideal for precision trenching with up to 3-ton excavators. The G5, a 30hp rock grinder, suits 2.5–6 ton machines, while the G5 Twin delivers 60hp and a 20" width—perfect for tight areas and noise-sensitive zones.

Mid-size options for versatile cutting

The D10 (40hp) features a 29" head for trenching and wall cutting. The D15 (55hp) and D20 (95hp) handle reinforced concrete and deeper cuts. The D30, with 150hp, is built for heavy demolition and deep excavation.

All models include robust drums, strong spur gears, and efficient hydraulic motors for consistent performance.

High power for demanding jobs

The G40 and G50 (both 190hp) offer serious cutting force for 30–60 ton machines. The G60 delivers 300hp for deeper rock and concrete work. At 536hp, the G125 leads the industry with the highest torque, ideal for large-scale tunneling, mining, and heavy-duty construction.

One cutter range, endless possibilities

From trenching to demolition, every Rockwheel rotary drum cutter is engineered for precision, low vibration, and durability. With powerful motors, rugged components, and the ability to cut rock at depth, these attachments are a reliable alternative to hydraulic hammers across the industry.

Equip Your Excavator with High-Precision Power

Rockwheel drum cutters deliver precise cutting, low vibration, and efficient performance across rock, concrete, and other tough materials. With powerful hydraulic motors and robust drums, they're built for trenching, demolition, and rock excavation.

Contact us to find the right attachment for your excavator and take on tough jobs with more power and less noise.