Rock Screeners: Rock-Screening Rake, Bucket, and Equipment

Rock Screeners: Rock-Screening Rake, Bucket, and Equipment

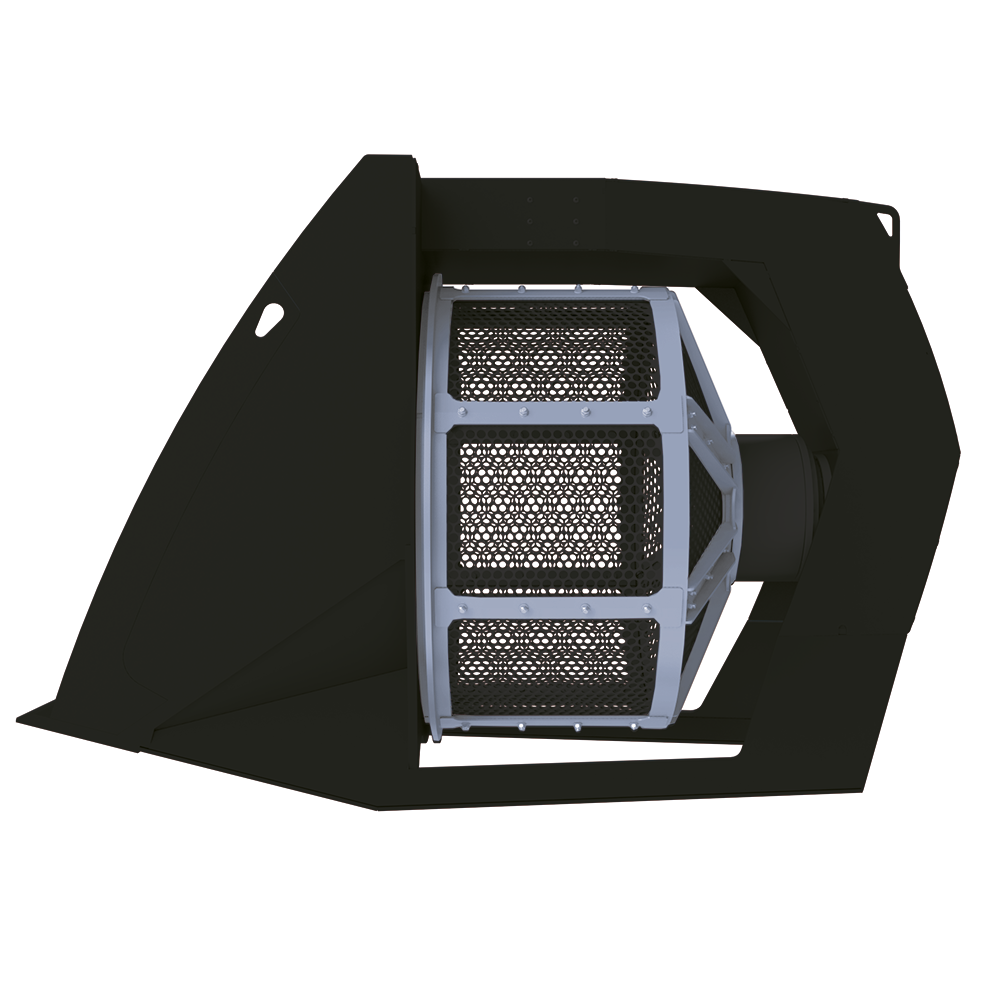

HD Series with XXL Hopper and Drum

(Formerly Hartl Screener) The Rockscreener XXL hopper and XXL drum volume can process more volume in a shorter time with uniform results.

The compact and stable structure of the frame ensures a reliable screening capacity with low running costs. This attachment enables materials to be separated more precisely. The exchangeable grids allow for sieving and screening in different, variable sizes. The grids can be used for pre-filtering (prior to crushing) and for final classification purposes.

Rockscreeners are ideal for working with natural rock, recycling, infrastructure, pipelines, landscaping, and sorting construction rubble. Built for land clearing in Florida and stock prep on tough job sites, this rock screening equipment handles heavy-duty applications from compost to rubble, delivering affordable, efficient results.

| Rockscreener Model | RSS 800 | |

| Excavator Class | tons | 3 - 9 |

| Required Flow Rate | GPM (l/min) | 5 (20) |

| Operating Pressure (Max) | psi (bar) | 1885 (130) |

| Screen Drum Diameter | in (mm) | 31.5 (800) |

| Screen Drum Depth | in (mm) | 19.7 (500) |

| Drum Volume | yd3 (m3) | 0.33 (0.25) |

| Total Load Capacity | yd3 (m3) | 0.79 (0.61) |

| Weight (w/o bracket) | lbs (kg) | 1320 (600) |

| RS 800 |

| 9 - 14 |

| 7 (26) |

| 1885 (130) |

| 31.5 (800) |

| 19.7 (500) |

| 0.33 (0.25) |

| 0.79 (0.60) |

| 1410 (640) |

| RS 1200 |

| 15 - 25 |

| 20 (75) |

| 2465 (170) |

| 47.5 (1200) |

| 29.5 (750) |

| 1.0 (0.76) |

| 2.6 (2.0) |

| 2690 (1220) |

| RS 1600 |

| 25 - 35 |

| 20 (75) |

| 2465 (170) |

| 63 (1600) |

| 43.5 (1100) |

| 2.5 (1.9) |

| 6.25 (4.8) |

| 5120 (2315) |

| RS 2000 |

| 35+ |

| 32 (120) |

| 2465 (170) |

| 78.75 (2000) |

| 43.5 (1100) |

| 4.5 (3.4) |

| 9.75 (7.5) |

| 10,150 (4600) |

Meet Rockzone Americas Rockscreeners

Rockzone Americas Rockscreeners are designed to handle high-volume material screening efficiently. These attachments, equipped with XXL hoppers and drums, process large volumes quickly and consistently. They also function as effective excavator screening buckets for various materials.

The compact and stable frame ensures reliable performance with low running costs, making them ideal for various applications, from natural rock and recycling to infrastructure and landscaping projects.

Each rock screening system is built to manage dirt, dust, and stock efficiently in tight spaces. These machines handle a wide range of materials, like pavers and light debris, delivering clean, sorted results. For operations aiming to sell processed material, the grizzly-style screen offers rugged performance you can count on.

Key Features of Our Rockscreeners

High volume processing

The XXL hopper and drum volume enable the Rockscreener to process more material in a shorter time, ensuring uniform results and high efficiency in the screening process.

Precise screening

Exchangeable grids allow for sieving and screening in different, variable sizes. These grids can be used for pre-filtering (prior to crushing) and for final classification purposes, providing precise material separation.

Durable construction

Compact and stable structure ensures reliable performance with low running costs. The Rockscreener is built to withstand tough job site conditions, providing long-lasting durability and outperforming a standard bucket in material handling.

Versatility

Suitable for various materials, including natural rock, construction rubble, soil, sand, and gravel. The Rockscreener is a versatile tool that can adapt to different job requirements, optimizing material processing on-site.

Applications

- Natural rock: Efficiently screens and processes natural rock, providing high-quality material for construction and landscaping projects.

- Recycling: Ideal for recycling operations, the Rockscreener can process and separate materials, reducing waste and supporting sustainable practices.

- Infrastructure and pipelines: Perfect for infrastructure projects, including pipeline construction, where precise material screening is crucial.

- Landscaping: Versatile in landscaping applications, the Rockscreener can handle soil, gravel, and sand, ensuring high-quality materials for various landscaping needs.

- Sorting construction rubble: Effectively sorts and processes construction rubble, separating useful materials and reducing disposal costs by removing oversized material. The Rockscreener can be used with a carrier machine for enhanced versatility.

Why Rockscreeners?

Rockzone Americas Rockscreeners are designed to deliver unmatched performance, versatility, and durability in material screening applications. These machines are the top choice for contractors and industries looking to optimize their screening processes.

Efficiency

The high volume processing capability and precise screening ensure efficient material handling, saving time and reducing operational costs. The optimized hydraulic flow contributes to its overall efficiency, even when operating at full load.

Versatility

Adaptable to a wide range of applications, Rockscreeners can process various materials including rock, soil, sand, and gravel, making them a valuable tool for different industries. Their versatile design meets the demands of the current market.

Durability

Built with robust materials, Rockscreeners are designed to withstand the harsh conditions of job sites, ensuring long-term reliability and low maintenance costs.

Precision

The exchangeable grids and precise screening capabilities allow for accurate material separation, enhancing the quality of the screened materials and supporting various project requirements.

By choosing Rockzone Americas Rockscreeners, you are investing in a high-performance solution that enhances efficiency, supports sustainability, and delivers reliable performance across multiple industries.

Achieve Superior Screening with Rockscreeners

Maximize your material processing efficiency with Rockzone Americas Rockscreeners. Experience the power and precision of our advanced screening technology.

Built to manage dust, shape stock for sale, and screen materials like pavers with grizzly-tough performance, this system fits a wide range of job types. It's a clear example of power and precision in a compact form.

With models available for a variety of excavator sizes and jobsite needs, it’s easy to find the right fit for your operation. Get a quote today.

Get a Quote