Tools to Break Up Soil: Power Through Excavation and Site Prep Like a Pro

Hard-packed soil has a way of stopping progress cold. Standard equipment hits its limits, and what should be a straightforward job quickly turns into a frustrating, slow-moving process. On large-scale projects, the right tools to break up soil aren’t just helpful—they're essential.

This blog takes a closer look at how to handle compacted, rocky, or clay-heavy terrain using serious equipment. From drum cutters like Rockwheels to soil mixers and rock crushers, we’ll explore what it really takes to keep excavation and site prep on track—even when the ground doesn't want to cooperate.

Key Takeaways

- Breaking up compacted or rocky ground requires high-performance equipment—not hand tools.

- Soil conditions vary drastically. Matching the right tool to the job ensures better results with less strain on your crew.

- RockZone Americas’ products like Rockwheels, Soil Mixers, and Rockcrushers are purpose-built for tough excavation and site prep work.

Know Your Soil Before You Dig

Not all ground is created equal. Some sites are soft and loamy, while others are riddled with rocks, hard clay, or compacted fill. Understanding what you're working with is the first step in choosing the right equipment.

Clay-heavy soil tends to dry like concrete and resists most standard digging tools. Rocky ground, on the other hand, not only slows down excavation—it can destroy gear not designed for impact. And compacted urban fill often includes debris or construction waste that requires separation before reuse.

Pro tip: If your excavator bucket is bouncing or barely penetrating, it's time to call in the heavy hitters.

Heavy-Duty Tools to Break Up Soil Faster and Smarter

When you're working with compacted soil, clay, or mixed rubble, standard digging equipment often isn’t enough. These conditions demand specialized tools to break up soil—tools built to cut, crush, and mix with precision while standing up to the realities of large-scale excavation.

From trenching to stabilization, here are proven methods and machines for working through the toughest ground conditions.

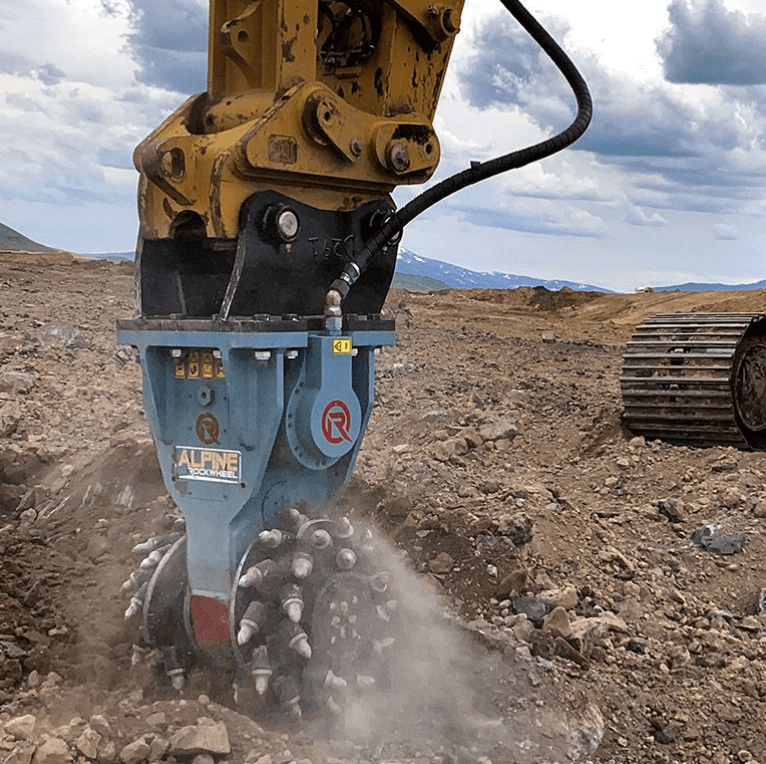

Drum cutters: Break through compacted and clay soil

Clay soil is notorious for resisting traditional excavation. It dries hard, holds water, and increases wear on standard buckets and shovels. Drum cutters, such as Rockwheels, are engineered to break through these dense layers efficiently.

They use powerful rotating drums to grind through compacted soil, rock, and even reinforced concrete—ideal for:

- Trenching near existing structures

- Digging in restricted-access zones

- Prepping utility lines or foundations

Their low-vibration design makes them suitable for working close to buildings or in sensitive areas without compromising power or control.

Soil mixers: Improve stability and structure on-site

In projects where ground stabilization is required, soil mixers offer an efficient solution. These attachments blend stabilizing agents such as lime, cement, or fly ash into unstable or wet soils, improving strength, cohesion, and long-term performance.

Common applications include:

- Preparing construction pads on unstable or moist terrain

- Strengthening subgrades for road building

- Reworking existing material to meet engineering specs

Rather than removing and replacing poor soil, these mixers treat it in place—reducing haul-off, cost, and environmental impact.

Rockcrushers: Break down rubble into reusable material

Demolition, site clearing, and excavation often generate excess rock, brick, and concrete. Instead of hauling it away, rockcrushers convert this hard material into usable backfill or subbase.

This process allows teams to:

- Break down large debris directly on-site

- Reuse crushed material for compaction or grading

- Save time on transport and dumping fees

Whether working on road prep, trench backfilling, or general site leveling, this approach keeps things moving.

Screeners and sorters: Clean fill, ready to use

When you're excavating or reprocessing fill, it’s common to encounter mixed dirt, aggregates, and debris. Screening attachments separate fine particles from oversized material, ensuring only quality fill is reused.

Rocksorters take it further, categorizing rock by size for reuse, disposal, or resale. This helps crews:

- Produce consistent fill for compaction or grading

- Remove unwanted debris and oversized material

- Prepare reliable sublayers for construction and roadbeds

These tools streamline material handling and reduce labor demands on the job site.

Cutter buckets: Dig and cut in one pass

When digging through overgrown, debris-laden, or mixed terrain, cutter buckets provide both excavation and cutting functionality. With reinforced blades, they’re made for:

- Slicing through roots and compacted sublayers

- Working efficiently in rough or rocky ground

- Reducing the need for multiple machines on-site

These attachments are especially useful in initial phases of land clearing or trenching, where mixed layers of soil, fill, and obstructions are common.

Soil Stabilization That Supports Better Excavation

On many job sites, especially those with compacted soil or high moisture content, the ground needs more than just breaking apart—it needs to be stabilized before excavation or construction can continue. This often involves blending materials like lime or cement into the existing soil to improve strength, consistency, and drainage.

Rather than removing poor material or hauling in engineered fill, stabilization can be done directly on-site using mechanical mixing. This approach helps prepare the ground more efficiently, especially when working across large or variable terrain.

Equipment such as high-capacity soil mixers can be used to integrate these binders evenly into the soil, reducing delays and minimizing the need for additional handling or transport.

This process is especially valuable when time, cost, and access to replacement material are limiting factors.

How We Power Through With RockZone Americas Tools

When the ground is dense, rocky, or deeply compacted, hand tools can only go so far. That’s where RockZone Americas makes the difference.

Our Rockwheels are powerful drum cutter attachments designed to cut through clay, compacted soil, concrete, and rock with low noise and minimal vibration. They’re ideal for trenching near existing structures, cutting utility access, prepping confined excavation zones, or working in sensitive areas where control is critical.

We also offer:

- Soil Mixers for blending manure, compost, and stabilizers

- Rockcrushers to turn rubble into backfill

- Rockscreeners and Rocksorters for precise material separation

- Cutter Buckets for efficient digging and cutting

All equipment is available for rent or purchase and is built to handle real hard work.

Need to cut through tough soil or solid rock? Call RockZone Americas today for expert advice and equipment that works as hard as you do.

Conclusion

Tough ground shouldn’t hold back your next big job. With specialized equipment from RockZone Americas—like Rockwheels, Soil Mixers, and Cutter Buckets—you can cut, crush, and conquer any terrain with confidence.

Dig deeper. Work smarter. Power through.

Frequently Asked Questions

What is the best equipment for breaking up hard soil and rock?

On large-scale projects, equipment like drum cutters, soil mixers, and hydraulic breakers are commonly used. These tools are designed to handle compacted soil, rock, and concrete with greater control and efficiency than standard digging attachments.

Can material from a rocky or demolished site be reused?

Yes. In many cases, concrete, rock, and mixed debris can be crushed and repurposed as backfill or base material. Screening and sorting equipment can help separate reusable soil from rubble, reducing both disposal and material costs.

What’s an efficient way to prepare compacted land for construction?

A common approach is to first break up the surface using mechanical cutters or rippers. Once loosened, the soil can be stabilized in place by mixing in binders like lime or cement, especially if drainage or structural support is a concern. The right combination of cutting and mixing attachments will depend on the site conditions and project requirements.