Big Rock Excavating: Proven Methods, Equipment, and Expert Tips

Every contractor knows that big rock excavating is no small task. It’s one of the toughest parts of site preparation, grading, or foundation work. Large rock formations, dense soil layers, and unpredictable terrain can slow progress, wear down equipment, and stretch project timelines.

Rock excavation requires strategy, precision, and the right machinery. A strong plan keeps your team safe, improves efficiency, and ensures quality results across every phase of the job.

At RockZone Americas, we’ve supported countless excavation and demolition projects that deal with big rock and tough conditions. In this guide, we’ll break down the key things you need to know—how to plan the job, choose equipment, manage costs, and protect your site from setbacks.

Key Takeaways

- Big rock excavations demand planning, precision, and the right equipment to keep projects efficient and safe.

- Choosing the right tools and techniques helps save time, reduce wear, and maintain quality on every job.

- With expert guidance and reliable attachments, even the toughest rock excavation projects become manageable.

Understanding the Challenges of Rock Excavation

Big rock excavations can challenge even the most experienced teams. The hardness, density, and structure of the rock determine how easily it can be broken and removed. Understanding these factors helps manage risk, time, and equipment use more effectively.

Some formations fracture naturally and are easier to excavate, while harder materials like granite demand powerful machinery and more time. Mixed layers of soil, gravel, and fractured stone add to the complexity of the work.

In areas with limited space or strict noise and vibration limits, mechanical cutting or grinding often replaces blasting. Careful planning and the right tools keep the team efficient, safe, and focused on maintaining consistent quality throughout the job.

Planning a Rock Excavation Project

Every successful excavation project starts with clear data and careful review. Before any digging begins, it’s important to understand the site’s structure and soil layers.

1. Conduct a site assessment: Hire a geotechnical engineer to take core samples or boring logs. This information helps you determine rock depth, type, and hardness. Reviewing these findings allows contractors to choose the best tools and methods for the job.

2. Define project goals: Decide whether the goal is full removal, trenching, or grading. Knowing what needs to be achieved saves time and reduces unnecessary excavation.

3. Protect utilities and surroundings: Always locate underground utilities before beginning work. In some regions, local regulations require clearance from utility companies. Proper site marking prevents costly damage and ensures compliance.

4. Establish a safety and waste plan: Plan for noise, dust, and debris management early. Use protective barriers, dust suppression systems, and proper haul routes to keep the site organized.

5. Review equipment needs: Measure the excavation depth, rock density, and available space. Then match the correct tools and attachments for the job. A solid plan keeps delays minimal and improves crew coordination.

Effective Methods for Removing Rock

No two big rock excavations are the same. The best method depends on rock hardness, land conditions, and available space. Choosing the right approach helps the whole team manage time, reduce wear on equipment, and keep excavation safe and efficient.

Drilling and blasting

This classic method remains one of the fastest for breaking down large rock masses. It involves drilling deep holes, inserting controlled charges, and detonating to fracture the rock. It’s best for open land or rural areas where vibration and noise control aren’t major concerns.

Licensed experts must handle this method to ensure compliance and safety.

Mechanical excavation

Mechanical excavation is often preferred for sites near residential or sensitive zones. It uses hydraulic hammers, rock breakers, or rotary cutters to chip away at the material with precision.

Excavators fitted with specialized attachments provide consistent results without relying on explosives. This method works well for detailed excavation, trenching, or grading where accuracy matters.

Hybrid excavation

Some excavation projects benefit from combining methods. Large sections of rock can be loosened through blasting, then refined using mechanical tools. This hybrid approach allows teams to work faster while maintaining control. It also minimizes vibration and dust when working near other structures.

Non-explosive alternatives

For areas where blasting isn’t possible, methods like hydro demolition, pressure bursting, or chemical expansion agents can break down rock quietly.

These options expand inside drilled holes, creating cracks without noise or vibration. They’re ideal when protecting nearby land, buildings, or utilities is a top priority.

Each of these excavation methods requires careful planning, reliable data, and the right tools. When teams understand the rock’s composition and site conditions, they can choose the safest and most productive solution, saving time and improving the quality of every job.

Essential Equipment for Rock Excavation

The success of big rock excavations often depends on using the right equipment.

Choosing tools that match the site’s demands helps improve efficiency, reduce wear, and ensure safety throughout the excavation. When paired with accurate data and good planning, the right machinery can turn even the toughest rock removal into a smooth operation.

Excavators

Modern excavators provide the power and flexibility needed for rock excavation. With high hydraulic strength, they can dig, lift, and move material efficiently.

When fitted with the right attachments, excavators become reliable tools for shaping land, removing rock, or performing grading tasks. They also allow teams to work faster and maintain better control over each phase of the project.

Hydraulic breakers and hammers

These heavy-duty tools deliver strong impact energy to fracture dense rock and concrete. They’re ideal for both vertical and horizontal excavation where accuracy and control are important.

Hydraulic hammers help minimize downtime by breaking material into manageable pieces quickly, improving workflow across the entire job.

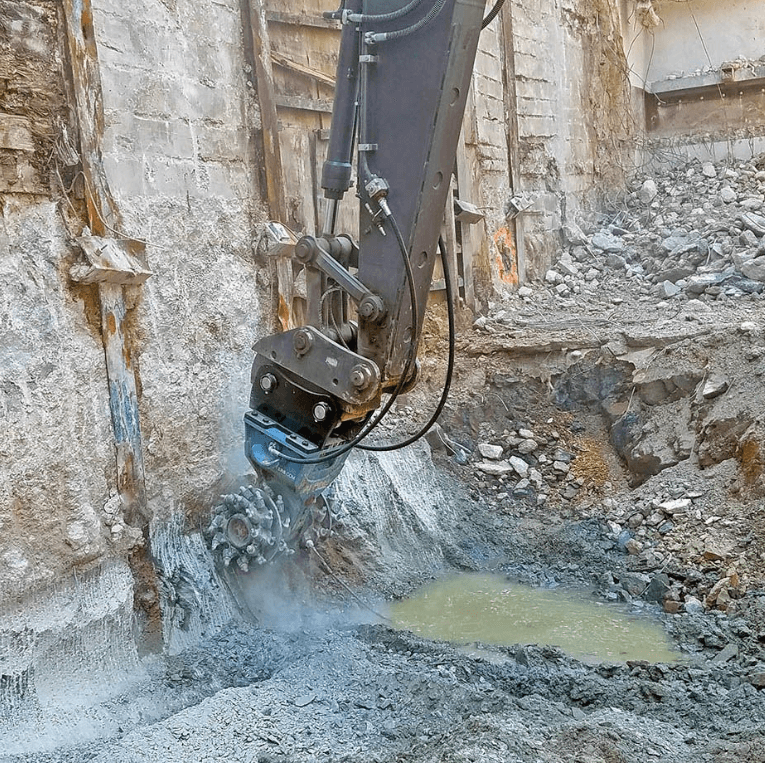

Rotary cutters and rockwheels

Rotary cutters and Rockwheels provide precision cutting for detailed excavation work. They grind through rock with limited vibration and low noise, making them suitable for urban areas and confined sites. They help maintain quality and safety while reducing disruption.

Watching these tools in action through project videos often helps teams understand how they improve cutting accuracy and productivity.

Crushers and screeners

After the rock is removed, crushers process large chunks into smaller aggregate for reuse or disposal. Screeners then separate materials based on size, keeping the site organized and efficient. This combination reduces hauling costs and supports eco-friendly waste management.

Safety and support gear

Strong excavation work relies on consistent safety checks and maintenance. Daily inspections of attachments, filters, and hydraulic systems help detect problems early. Dust suppression systems and protective barriers keep air quality safe and visibility clear for the whole team.

When you measure results, review equipment performance, and apply the right settings for each job, you can provide better outcomes and protect your investment. The right mix of machinery and planning ensures every excavation phase runs safely, smoothly, and on time.

Factors That Influence Excavation Strategy

Choosing the right approach involves more than just the hardness of the rock. A few important factors determine how to plan and execute rock excavation effectively.

Rock type and density: Harder rock types like granite or basalt require hydraulic hammers or cutting attachments, while softer rock can often be handled with ripping tools. Understanding the rock’s strength helps contractors choose methods that minimize wear on equipment.

Site accessibility: In confined or urban environments, blasting may not be possible. Mechanical or non-explosive methods offer safer, low-vibration alternatives that keep nearby structures protected.

Environmental and safety regulations: Noise, dust, and debris control are crucial to compliance. Using attachments that limit vibration and airborne particles helps maintain environmental standards.

Project budget and schedule: Balancing speed and cost efficiency is key. Advanced attachments and efficient excavators reduce downtime and fuel consumption, helping contractors stay within budget.

Crew experience: A skilled team understands how to read site data, measure performance, and adapt quickly to challenges. Experienced operators can identify problem areas early and prevent costly delays.

Managing Cost and Time in Rock Excavation

Rock excavation is one of the most expensive parts of site preparation, but careful planning helps manage costs.

- Labor costs: Skilled operators and trained crews work faster and safer, reducing delays.

- Equipment rentals: Investing in high-quality attachments may cost more upfront, but it saves money over time through reduced wear and better productivity.

- Disposal fees: Recycling rock into aggregate minimizes hauling costs and provides reusable material.

- Unexpected conditions: Geotechnical surveys help predict challenges and prevent overruns.

- Maintenance: Regular inspection and service extend the lifespan of machines and attachments.

Tracking progress with accurate data and reviewing performance daily helps teams improve efficiency and maintain high quality on every job.

Best Safety Practices for Rock Excavation

Safety should guide every decision on the excavation site. Rock excavation involves heavy machinery, powerful tools, and unpredictable ground conditions.

- Use proper PPE: Hard hats, gloves, safety glasses, and steel-toed boots protect against debris and falling material.

- Control dust and debris: Use water sprays or barriers to minimize airborne particles.

- Monitor equipment condition: Inspect hydraulic systems, cutters, and wear parts before and after each shift.

- Maintain clear communication: Regular briefings help the whole team stay aligned.

- Manage work zones: Keep unauthorized personnel out and post clear signage around excavation areas.

- Prepare for emergencies: Have first-aid and response plans ready for mechanical failures or site hazards.

Following these safety measures keeps every project compliant, efficient, and accident-free.

RockZone Americas: Your Partner in Tough Excavation Projects

Tough terrain, dense rock, and tight schedules can make big rock excavations challenging. At RockZone Americas, we help tackle these problems with reliable, high-performance attachments built for power, precision, and efficiency.

Our equipment handles demanding site conditions while maintaining control and accuracy:

- Rockwheels: Deliver precise, low-vibration cutting for trenching, grading, and shaping rock or concrete.

- Rockcrushers: Process large rock or concrete into reusable aggregate, cutting disposal costs and improving workflow.

- Rockscreeners: Sort and separate materials on-site for faster cleanup and better organization.

- Cutter Buckets: Combine cutting, excavation, and material handling in one attachment to save time and reduce equipment swaps.

Each RockZone attachment fits most excavators and performs efficiently across different site types. With decades of experience in rock excavation, demolition, and material processing, we provide the tools and expertise you need to keep every project safe, productive, and on schedule.

If you’re facing challenges with hard rock or complex site conditions, call our team. We’ll help you choose the right equipment, improve performance, and get the job done efficiently from start to finish.

Conclusion

Big rock excavations require planning, patience, and the right approach. Understanding the site conditions, selecting proper methods, and using dependable equipment all play a role in making the process smoother and safer.

Success depends on preparation and precision. When teams take the time to measure conditions, adjust techniques, and use tools designed for efficiency, even the toughest terrain becomes manageable.

Excavating rock isn’t only about breaking material - it’s about protecting the site, maintaining quality, and staying on schedule. With the right strategy and equipment, any project can be completed safely, efficiently, and to a high standard.

Frequently Asked Questions

How much does rock excavation cost?

Rock excavation typically costs $40–$200 per cubic yard, depending on rock type, site access, and method.

Harder rock, like granite, is more expensive to remove, while fractured rock costs less. Mechanical excavation is ideal for small or urban sites, while blasting suits large open areas. Recycling rock as aggregate helps reduce disposal fees and overall project costs.

What makes big rock excavations challenging?

They’re difficult because of the rock’s density and unpredictable site conditions. Hard materials, vibration limits, and nearby structures require precise tools and careful planning to keep work safe and efficient.

How does the whole team stay safe during excavation?

The whole team stays safe through clear communication, daily equipment checks, and proper PPE. Controlling dust, marking zones, and holding safety briefings prevent accidents and keep the project running smoothly.